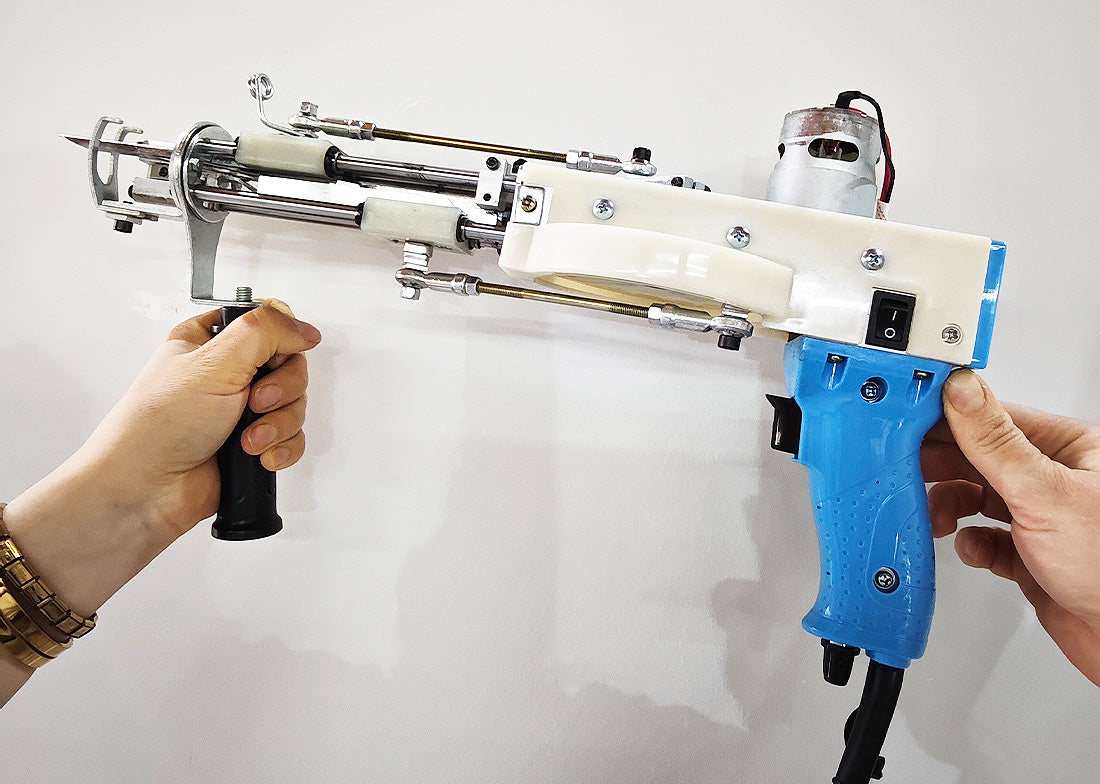

1. The gun is not receiving electricity

Possible Causes:

- The cable may be damaged.

- There may be a problem with the outlet or power source.

- The fuse inside the gun may have blown.

Solution:

- Check if there is power by plugging it into a different outlet.

- Examine the cable carefully. Replace it if it is frayed or broken.

- Unplug the gun before opening it. Check the fuse box and replace the fuse if necessary.

2. The thread does not pass or gets stuck

Possible Causes:

- The thread may have been placed incorrectly.

- The thread may be stuck inside the gun.

- The thread may not be passing through the gun needle.

Solution:

- Remove the thread and place it properly again.

- Check the gun's thread guide holes and remove the jammed thread.

- Using a thin crochet hook or wire, pass the thread through the tip of the needle.

3. Tufting Gun Operates Too Slowly or Erratically

Possible Causes:

- The gun's motor may be dirty or dusty.

- There may be a lack of oil in the gears.

- The power supply may be insufficient.

Solution:

- Turn off the gun and unplug it. Open the motor and clean it with a brush.

- Lubricate the gears by applying a thin layer of machine oil.

- Connect the gun to a stronger electrical source.

4. Threads Are Not Secured Properly

Possible Causes:

- The fabric is not stretchy enough.

- The gun's needle may be dull.

- The wrong type of thread may be used.

Solution:

- Stretch your fabric tighter across the hoop or frame.

- Check the gun needle and replace if necessary.

- Be careful to use threads specifically produced for tufting.

5. The gun is extremely noisy while operating.

Possible Causes:

- There may be backlash in the gears.

- The screws may be loose.

- There may be wear on the engine part.

Solution:

- Check and tighten the screws inside the gun.

- Make sure the gears are aligned.

- If there is excessive wear on the engine, consult a technician.

6. Gun Trigger Doesn't Respond

Possible Causes:

- The trigger mechanism may be jammed.

- There may be a problem with the electrical connection.

- There may be a broken part in the internal mechanisms.

Solution:

- Unplug the gun and check the trigger. If it is stuck, carefully loosen it.

- Check the electrical connection again.

- If the trigger mechanism is broken or cracked, contact the manufacturer.

7. The gun does not cut the thread (for cut pleat models)

Possible Causes:

- The cutting blade may be dull.

- The cutter mechanism may be misaligned.

Solution:

- Remove the blade and sharpen it or replace it with a new one.

- Carefully adjust the cutter mechanism to ensure the blade is in the correct position.

Preventive Maintenance Tips

- Clean the gun after each use.

- Lubricate the motor and gears monthly.

- Check the gun's thread passage channels regularly.

- Do not over-force the gun; pay attention to the speed and pressure settings in the user manual.

Keeping your tufting gun running smoothly increases the quality and speed of your projects. By following this guide, you can easily resolve potential issues and keep your production process running smoothly.